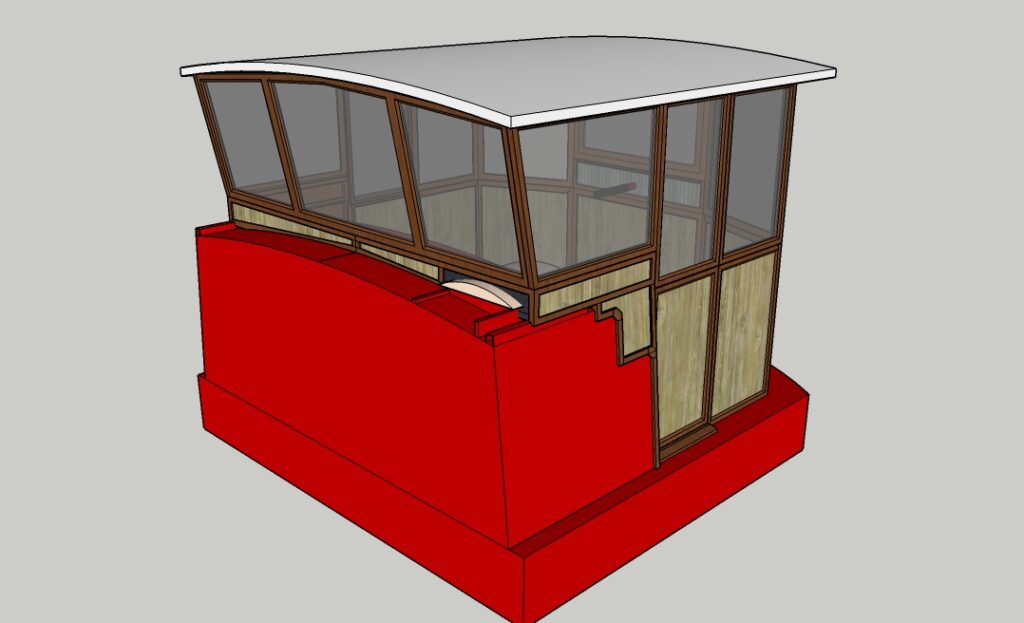

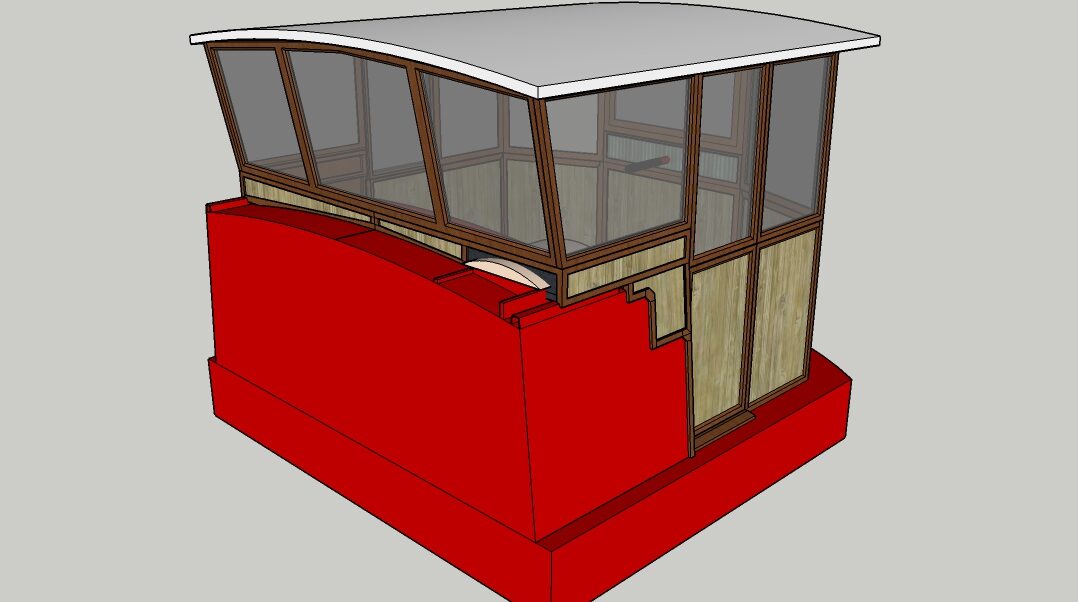

This is typical of a wheelhouse build, taking the project from design through to finish. We have used this design, or a variation of it, on many wheelhouse projects. This blog goes through some details of how we do this.

The clients needed more space and wanted to turn the stern deck into a useful, and beautiful, exterior space. It also had to be collapsible. This was necessary so that the boat would still be able to get through tunnels and under bridges when it left its mooring. All elements more than a foot or so above the boat cabin roof had to be removable with two people. We had weight limits and engineering challenges to consider.

After in-depth discussion of specification and requirements, we produced detailed drawings of the overall wheelhouse and the specific details. The way that the different parts would connect was considered. We also planned how the piece would work as a whole. Working out how water would be channelled from the roof and how it would escape from inside was essential. This area would still be an exterior area at times.

They wanted as much light as possible. Indeed, we ultimately swapped out one of the lower panels for glass as well, where it was originally timber. Thus, it wouldn’t block the sunrise on the back door. The upper panels are toughened glass, and they let in lots of light. We made sure that there were several opening points. This ensures that on a hot day it didn’t become a furnace!

To make it collapsible, all the upper row are hinged on to the lower, fixed panels. This means once the roof panels are off and stacked on to the boat roof, you can lower each of the panels. They can also be removed entirely if required, as the hinges are all lift-offs. Speaking of storing the roof on the boat, the curve of the roof was based on the curve of the boat roof. This produces a sympathetic line with the rest of the boat.

We’ve done a few wheelhouses and parts of wheelhouses. A couple of the photos (the ceiling and the close-up on the detail of the roof end support) are actually from another wheelhouse we built. This is because I didn’t have enough good photos of this one. The designs are similar and all is our work. However, of the wheelhouse work we have done, this one is still hands down my favourite.

[{"id":"5284","link":"https:\/\/cluettcarpentry.com\/social-media-posts-stories-announcing-this-is-unboxing\/","name":"social-media-posts-stories-announcing-this-is-unboxing","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2026\/02\/aioseo-ai-facebook-stories-unboxi-medium-auto-landscape-20260212-122419.png","alt":"Facebook and Instagram Stories - Unboxing products from our shop (https:\/\/shop.cluettcarpentry.com)"},"title":"Social Media Posts - Stories - Announcing this is unboxing","author":{"name":"admin","link":"https:\/\/cluettcarpentry.com\/author\/admin_zk72tdkv\/"},"date":"Feb 15, 2026","dateGMT":"2026-02-15 12:28:14","modifiedDate":"2026-02-12 12:29:26","modifiedDateGMT":"2026-02-12 12:29:26","commentCount":"0","commentStatus":"open","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/as-seen-on\/\" rel=\"category tag\">As Seen On<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/as-seen-on\/\" rel=\"category tag\">As Seen On<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":1,"sec":8},"status":"publish","content":"We\u2019ve recently been featured in a series of posts across Instagram and Facebook Stories, and we\u2019re excited about the buzz they\u2019ve created. Since Stories are"},{"id":"5183","link":"https:\/\/cluettcarpentry.com\/s-is-for-shelves-see-the-best-ideas\/","name":"s-is-for-shelves-see-the-best-ideas","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2026\/01\/SisForShelves.jpg","alt":"S is for Shelves: Main Picture"},"title":"S is for Shelves! See the best ideas","author":{"name":"Dan","link":"https:\/\/cluettcarpentry.com\/author\/dan\/"},"date":"Feb 1, 2026","dateGMT":"2026-02-01 13:22:52","modifiedDate":"2026-02-01 13:26:20","modifiedDateGMT":"2026-02-01 13:26:20","commentCount":"1","commentStatus":"open","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":2,"sec":45},"status":"publish","content":"S is for Shelves! Back again on shelves. I have covered this in part with other articles, but I wanted to do a whole piece"},{"id":"5152","link":"https:\/\/cluettcarpentry.com\/w-is-for-wheelhouse-an-awesome-and-remarkable-boat-part\/","name":"w-is-for-wheelhouse-an-awesome-and-remarkable-boat-part","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2026\/01\/WheeleHouse-e1769213314652.jpg","alt":"W is for Wheelhouse"},"title":"W is for Wheelhouse, An Awesome and Remarkable Boat Part","author":{"name":"Dan","link":"https:\/\/cluettcarpentry.com\/author\/dan\/"},"date":"Jan 24, 2026","dateGMT":"2026-01-24 00:22:25","modifiedDate":"2026-01-24 00:22:46","modifiedDateGMT":"2026-01-24 00:22:46","commentCount":"4","commentStatus":"open","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":4,"sec":13},"status":"publish","content":"W is for Wheelhouse A wheelhouse is one of my favourite jobs. There is lots of interesting designing to resolve, the job itself is complex"},{"id":"5166","link":"https:\/\/cluettcarpentry.com\/towpath-talk-characters-of-the-cut-january-2026\/","name":"towpath-talk-characters-of-the-cut-january-2026","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2026\/01\/screenshot-2026-01-05-085630-638x765-1.webp","alt":"Towpath Talk Magazine, January 2026"},"title":"Towpath Talk - Characters of the Cut - January 2026","author":{"name":"admin","link":"https:\/\/cluettcarpentry.com\/author\/admin_zk72tdkv\/"},"date":"Jan 15, 2026","dateGMT":"2026-01-15 21:57:39","modifiedDate":"2026-01-25 00:03:59","modifiedDateGMT":"2026-01-25 00:03:59","commentCount":"3","commentStatus":"open","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/as-seen-on\/\" rel=\"category tag\">As Seen On<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/as-seen-on\/\" rel=\"category tag\">As Seen On<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":0,"sec":54},"status":"publish","content":"Cluett Carpentry Ltd. has once again garnered significant media attention, with a detailed feature now available both in print and online. The article has been"},{"id":"4984","link":"https:\/\/cluettcarpentry.com\/new-years-sale-celebrate-with-20-off-everything\/","name":"new-years-sale-celebrate-with-20-off-everything","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2026\/01\/Cluett-Carpentry-New-Years-Sale-scaled.jpg","alt":"New Year's Sale 2026 - Use Code NewYear2026"},"title":"New Year's Sale: Celebrate with 20% Off Everything","author":{"name":"admin","link":"https:\/\/cluettcarpentry.com\/author\/admin_zk72tdkv\/"},"date":"Jan 5, 2026","dateGMT":"2026-01-05 00:04:29","modifiedDate":"2026-01-23 23:28:54","modifiedDateGMT":"2026-01-23 23:28:54","commentCount":"3","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":0,"sec":51},"status":"publish","content":"As we welcome the new year, we are excited to announce our exclusive New Year's Sale, offering a generous 20% discount on all products and"},{"id":"4725","link":"https:\/\/cluettcarpentry.com\/k-is-for-kitchens-what-you-need-to-know\/","name":"k-is-for-kitchens-what-you-need-to-know","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2025\/12\/01-Main-Photo.jpg","alt":"K is for Kitchens"},"title":"K is for Kitchens - What you need to Know","author":{"name":"Dan","link":"https:\/\/cluettcarpentry.com\/author\/dan\/"},"date":"Dec 4, 2025","dateGMT":"2025-12-04 23:50:15","modifiedDate":"2026-01-23 23:29:13","modifiedDateGMT":"2026-01-23 23:29:13","commentCount":"6","commentStatus":"open","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":1,"sec":34},"status":"publish","content":"K is for Kitchens: Okay, so in truth, a big part of this article is just to show off some of the beautiful kitchens we"},{"id":"4645","link":"https:\/\/cluettcarpentry.com\/important-update-on-bespoke-orders-at-cluett-carpentry\/","name":"important-update-on-bespoke-orders-at-cluett-carpentry","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2025\/12\/aioseo-ai-important-update-medium-auto-landscape-20251205-092529.png","alt":"Important Update about Bespoke orders"},"title":"Important Update on Bespoke Orders at Cluett Carpentry","author":{"name":"admin","link":"https:\/\/cluettcarpentry.com\/author\/admin_zk72tdkv\/"},"date":"Nov 30, 2025","dateGMT":"2025-11-30 10:26:38","modifiedDate":"2026-01-23 23:29:33","modifiedDateGMT":"2026-01-23 23:29:33","commentCount":"1","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":1,"sec":36},"status":"publish","content":"Update on Bespoke Orders. At Cluett Carpentry, we pride ourselves on crafting high-quality, beautifully designed bespoke pieces\u2014made with care, precision, and the personal touch that"},{"id":"4573","link":"https:\/\/cluettcarpentry.com\/the-breaks-are-on-the-bunting-is-down-find-out-more-now\/","name":"the-breaks-are-on-the-bunting-is-down-find-out-more-now","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2025\/11\/kelsey-todd-C76wb-e_djU-unsplash1.jpg","alt":"Early Access Black Friday Event Finished Early"},"title":"The Breaks Are On, the bunting is down - Find out More Now","author":{"name":"admin","link":"https:\/\/cluettcarpentry.com\/author\/admin_zk72tdkv\/"},"date":"Nov 18, 2025","dateGMT":"2025-11-18 16:30:06","modifiedDate":"2026-01-23 23:30:34","modifiedDateGMT":"2026-01-23 23:30:34","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":1,"sec":30},"status":"publish","content":"Black Friday Early Access: The Breaks Are On, and the Bunting Is Down at Cluett Carpentry What a whirlwind it\u2019s been! Our Black Friday Early"},{"id":"4549","link":"https:\/\/cluettcarpentry.com\/black-friday-early-access-sale-update-find-out-more\/","name":"black-friday-early-access-sale-update-find-out-more","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2025\/11\/CluettCarpentryBFEA-e1763136536225.png","alt":"Black Friday Early Access Update"},"title":"Black Friday Early Access Sale Update - Find Out More","author":{"name":"admin","link":"https:\/\/cluettcarpentry.com\/author\/admin_zk72tdkv\/"},"date":"Nov 15, 2025","dateGMT":"2025-11-15 14:27:17","modifiedDate":"2026-01-23 23:30:55","modifiedDateGMT":"2026-01-23 23:30:55","commentCount":"1","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":1,"sec":17},"status":"publish","content":"Black Friday Early Access Sale Update. We\u2019re excited to share that our Early Access Black Friday event is going exceptionally well so far! At our"},{"id":"4544","link":"https:\/\/cluettcarpentry.com\/b-is-for-bedrooms-a-tantalizing-look-at-the-challenge\/","name":"b-is-for-bedrooms-a-tantalizing-look-at-the-challenge","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2025\/11\/IMG20240114161317-scaled.jpg","alt":"B is for Bedroom - This picture shows how to maximise the space in a narrowboat."},"title":"B is for Bedrooms! A tantalizing look at the challenge.","author":{"name":"Dan","link":"https:\/\/cluettcarpentry.com\/author\/dan\/"},"date":"Nov 14, 2025","dateGMT":"2025-11-14 11:44:49","modifiedDate":"2025-11-14 11:44:49","modifiedDateGMT":"2025-11-14 11:44:49","commentCount":"0","commentStatus":"open","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":2,"sec":5},"status":"publish","content":"B is for Bedrooms! A tantalizing look at the challenge of an often-overlooked room in the boat. There is so much scope for storage and"},{"id":"4420","link":"https:\/\/cluettcarpentry.com\/get-ready-for-tempting-epic-savings-our-black-friday-early-access-sale-is-here-%f0%9f%8e%89\/","name":"get-ready-for-tempting-epic-savings-our-black-friday-early-access-sale-is-here-","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2025\/11\/BFEA25.jpg","alt":"Black Friday Early Access 2025 - BFEA25"},"title":"Get Ready for Tempting Epic Savings: Our Black Friday Early Access Sale is Here! \ud83c\udf89","author":{"name":"admin","link":"https:\/\/cluettcarpentry.com\/author\/admin_zk72tdkv\/"},"date":"Nov 8, 2025","dateGMT":"2025-11-08 23:17:45","modifiedDate":"2026-01-23 23:31:16","modifiedDateGMT":"2026-01-23 23:31:16","commentCount":"2","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/latest-news\/\" rel=\"category tag\">News<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":1,"sec":19},"status":"publish","content":"The biggest shopping season of the year is officially underway \u2014 and we\u2019re giving you a head start! Our Black Friday Early Access Sale is"},{"id":"4194","link":"https:\/\/cluettcarpentry.com\/tips-on-buying-a-boat-what-to-look-out-for-to-avoid-disastrous-results\/","name":"tips-on-buying-a-boat-what-to-look-out-for-to-avoid-disastrous-results","thumbnail":{"url":"https:\/\/cluettcarpentry.com\/wp-content\/uploads\/2025\/10\/delph1-600x382-1.jpg","alt":"Tips for buying a boat"},"title":"Tips on Buying a Boat; what to look out for to avoid disastrous results","author":{"name":"Dan","link":"https:\/\/cluettcarpentry.com\/author\/dan\/"},"date":"Oct 24, 2025","dateGMT":"2025-10-24 16:38:41","modifiedDate":"2025-11-14 11:45:06","modifiedDateGMT":"2025-11-14 11:45:06","commentCount":"1","commentStatus":"open","categories":{"coma":"<a href=\"https:\/\/cluettcarpentry.com\/category\/diy-tips\/\" rel=\"category tag\">DIY Tips<\/a>, <a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>","space":"<a href=\"https:\/\/cluettcarpentry.com\/category\/diy-tips\/\" rel=\"category tag\">DIY Tips<\/a> <a href=\"https:\/\/cluettcarpentry.com\/category\/the-a-to-z-of-narrowboats\/\" rel=\"category tag\">The A to Z of Narrowboats<\/a>"},"taxonomies":{"post_tag":""},"readTime":{"min":4,"sec":23},"status":"publish","content":"Tips on buying a boat, particularly a narrowboat. It is a big decision, and it can feel like the Wild West out there, especially if"}]